Okay Gilbert, I'll see if I can get Dan to bring it home from work so I can get some pics for you. The metal case speedos are close to 2 15/16'' diameter and the bezels are closer to 2 31/32'' diameter.The one speedo I opened up, the spring had broken. I reattached the spring, but it was a little shorter from being broken, and the speedo no longer read the correct speed.

I am very interested in the ring your friend has made to remove the bezels on these speedos. I have just been prying up the folded over edge on the back all the way around the circumference until the bezel can clear the lip of the speedo body. This works, but after re-installation it leaves the bezels a little scratched and lumpy.

I'll have to re-open up the old black face cadet and take a closer look.

Thanks again msrfan for all the helpful information.

Gilbert

Vintage Mechanical Speedometers

- Thread starter msrfan

- Start date

Hey silverbear, I don't know what mods would make them hold up better. Maybe some kind of shock mount with rubber bushings. That little hair spring on the needle is pretty delicate and lets it jump around a bit, but I usually don't look at the speedo until I'm cruising on a smooth road.Signing on to this thread. I have a few of the mechanical type gathered from donor bikes through the years, but had the impression they would not hold up under speed. Maybe we can modify them so that they will...

SB

Cool, let us know how it works. When I first started racing desert enduros in the 70's, I had a VDO speedo with a resettable tripmeter that held up really well, but the cable always got snagged on bushes and rocks. It took a while for me to realize I didn't need anything but an odmeter for enduro racing, so I changed to mechanical odos then later to electronic units with a magnetic pickup on the spokes.Thank you sir for the great suggestions and for the excellent pix of your collection, I really enjoy all the older bike stuff, I ordered that coughin shaped speedometer from Lithuania I found online, Im gonna give it a try and see if my results are better with it than they have been with the others I've tried.

Map

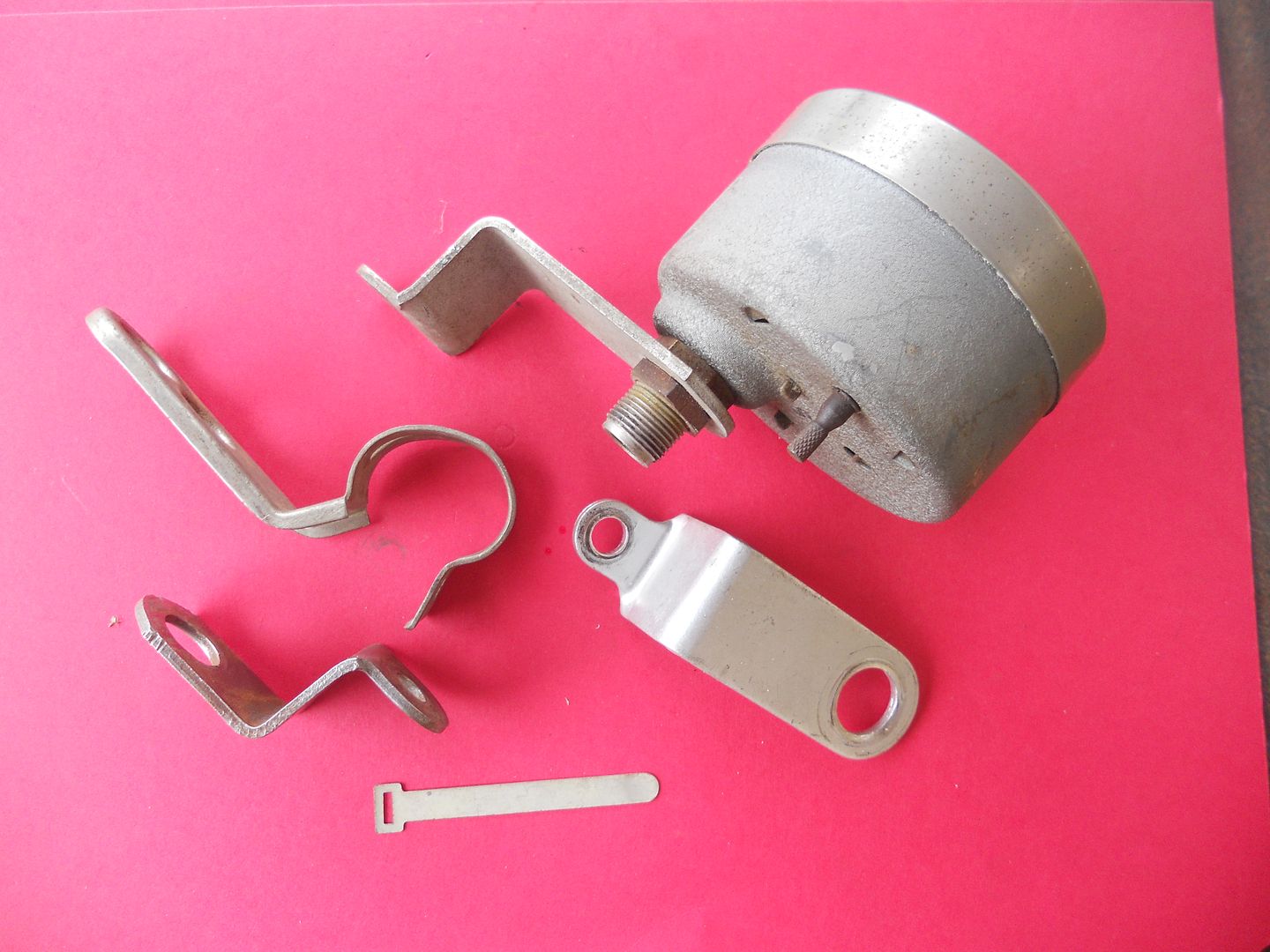

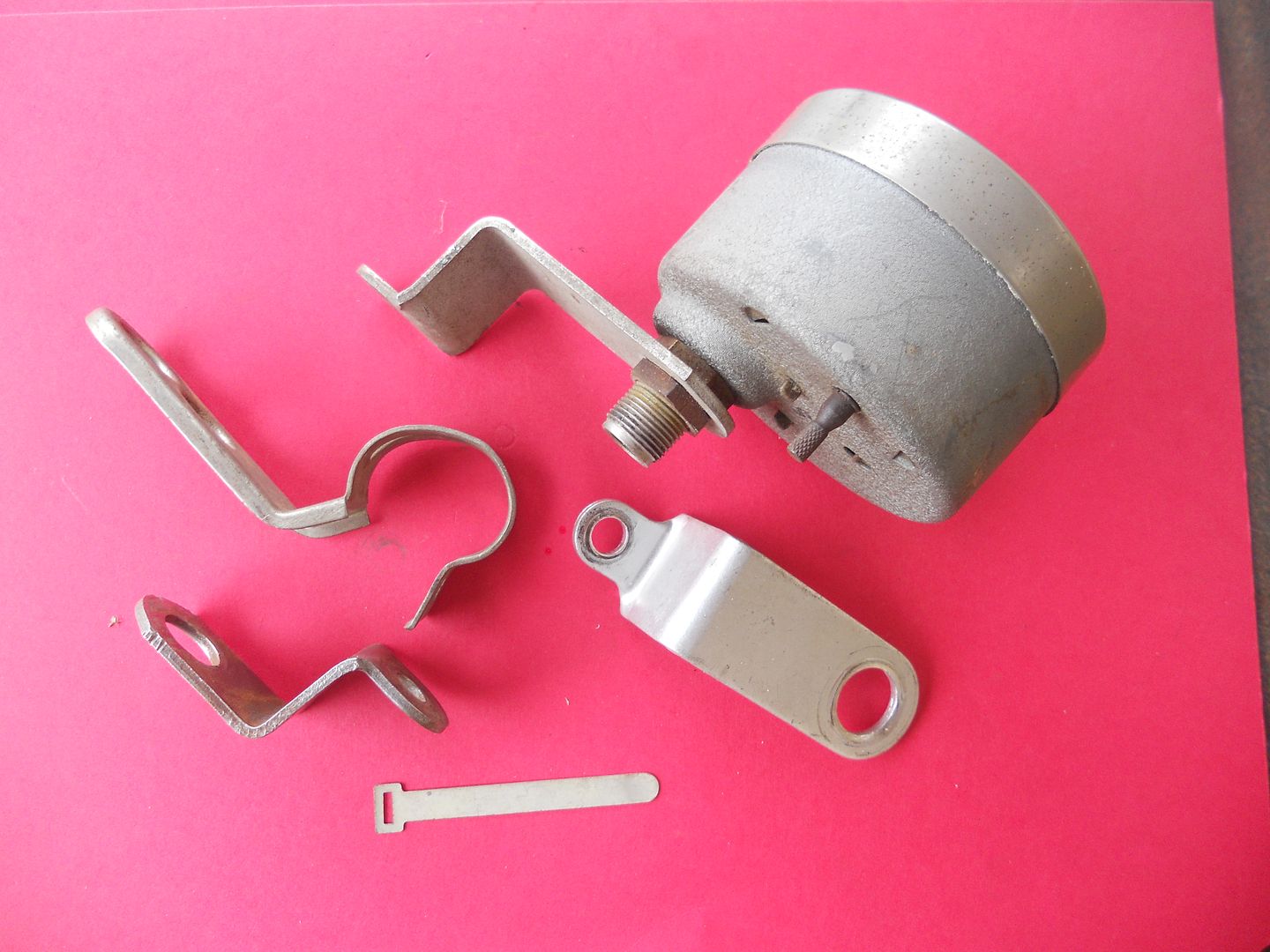

Sometimes you can't use the brackets and mounts intended for these speedos even though there's several variations.

I had to cut one shorter and use the straight portion in order for my speedo to clear my Whizzer tank. Luckily the cable was long enough to accommodate.

Then I had to make a bracket to surround the drive in order for my fender brace to attach. That story is in the Whizzer threads.

I had to cut one shorter and use the straight portion in order for my speedo to clear my Whizzer tank. Luckily the cable was long enough to accommodate.

Then I had to make a bracket to surround the drive in order for my fender brace to attach. That story is in the Whizzer threads.

I used to have an old Phillips 3 speed middleweight with a Huret speedometer with the little red friction drive wheel that rode on the front tire's sidewall. It was a flimsy bit of stuff but was fairly accurate.

I'm seeing just the Huret speedometer heads on Ebay for these things approaching $100.00!

Cannot imagine what a complete NIB Huret would go for now.

I'm seeing just the Huret speedometer heads on Ebay for these things approaching $100.00!

Cannot imagine what a complete NIB Huret would go for now.

Yeah, most of those are vintage Sting Ray parts. Those guys will pay almost anything for an official part or accessory.

I couldn’t agree more about the "just looks right" of a mechanical speedo on a vintage or antique bicycle!

Thanks for this thread!

-Kirk

Thanks for this thread!

-Kirk

I used one for my retro 1909 project...

It's a Stewart Warner, but I believe it's a newer one from the 60’ or 70’s as it mostly made of plastic parts including the case.

Cosmetically-

I made a new period correct “Corbin Screw Corporation” face plate in Photoshop, had a local copy center print a color copy and laminate it for durability. It just sits on top of the original plate and the bezel cover and 2 existing face screws hold it in place.

I painted the case to match the patina of my bike.

And I covered the cable with a couple of screen door springs and replaced the plastic nuts with some antique brass pipe fittings.

I also converted the MIJ driver from 2 to 1 gears so I could run it on the right side of a big Yamaha brake drum I ended up using.

But these systems are somewhat fragile so I’ve also made a few structural reinforcements over time-

After vibrations had broken a couple of the original thin mounting brackets I replaced with a seat tube clamp and a heavy chunk of flat stock attached to the handle bars.

On the driver I welded a little plate that fits over pot metal boss that the cable attached to. It had vibrated loose and would spin around which made it hard to firmly attach the cable and was also at risk of completely falling off.

The weakest link I believe is the tab that fits into to hub (or more commonly between The spokes). Any kind of small resistance and it will fold over. Once this happens it’s weakened and will do it all the time!

I simply welded a 1/4” bolt to mine and slopped some bead up around the top edge of the slotted disc for a little extra strength. A little ugly, but so far it’s held up well, 0 failures!

After about 700 miles the speedometer needle began to bounce at higher speeds. Cleaning and relubercating the cable would help but still over time it continuned to get worse. At around 1100 miles it finally failed completely and locked up (This is what first bent the tab mentioned above)

But the entire internal works are held in place with a single screw, so I just replaced them with another matching old unit. And I was able to move the dials from below to match the pervious miles.

At 1534 miles everything was still working great!

-Kirk

It's a Stewart Warner, but I believe it's a newer one from the 60’ or 70’s as it mostly made of plastic parts including the case.

Cosmetically-

I made a new period correct “Corbin Screw Corporation” face plate in Photoshop, had a local copy center print a color copy and laminate it for durability. It just sits on top of the original plate and the bezel cover and 2 existing face screws hold it in place.

I painted the case to match the patina of my bike.

And I covered the cable with a couple of screen door springs and replaced the plastic nuts with some antique brass pipe fittings.

I also converted the MIJ driver from 2 to 1 gears so I could run it on the right side of a big Yamaha brake drum I ended up using.

But these systems are somewhat fragile so I’ve also made a few structural reinforcements over time-

After vibrations had broken a couple of the original thin mounting brackets I replaced with a seat tube clamp and a heavy chunk of flat stock attached to the handle bars.

On the driver I welded a little plate that fits over pot metal boss that the cable attached to. It had vibrated loose and would spin around which made it hard to firmly attach the cable and was also at risk of completely falling off.

The weakest link I believe is the tab that fits into to hub (or more commonly between The spokes). Any kind of small resistance and it will fold over. Once this happens it’s weakened and will do it all the time!

I simply welded a 1/4” bolt to mine and slopped some bead up around the top edge of the slotted disc for a little extra strength. A little ugly, but so far it’s held up well, 0 failures!

After about 700 miles the speedometer needle began to bounce at higher speeds. Cleaning and relubercating the cable would help but still over time it continuned to get worse. At around 1100 miles it finally failed completely and locked up (This is what first bent the tab mentioned above)

But the entire internal works are held in place with a single screw, so I just replaced them with another matching old unit. And I was able to move the dials from below to match the pervious miles.

At 1534 miles everything was still working great!

-Kirk

Last edited: