Don't know what happened to my previous thread. I did an edit and when I tried to submit it the post got lost completely.

So..

Just needs some re-engineering to lockout the planetary section to provide 1:1. Any ideas?

If this approach has been discussed already then please don't blame me. Blame the search function. I searched for "steering quickener" and came up with nothing.

I was googling for a two speed gearbox that I can use for hi/lo range in a build. Not an automatic, centrifugal-clutch, two-speed transmission. Only a simple, robust, gearbox that would provide selectable Hi/Lo in a build like some of the 70's era trailbikes. There is nothing like this, from what I could find, in a simple gearhead or gearbox. There are a few that are cobbled together with chains and dog clutches and appear to take up lots of space and weight.

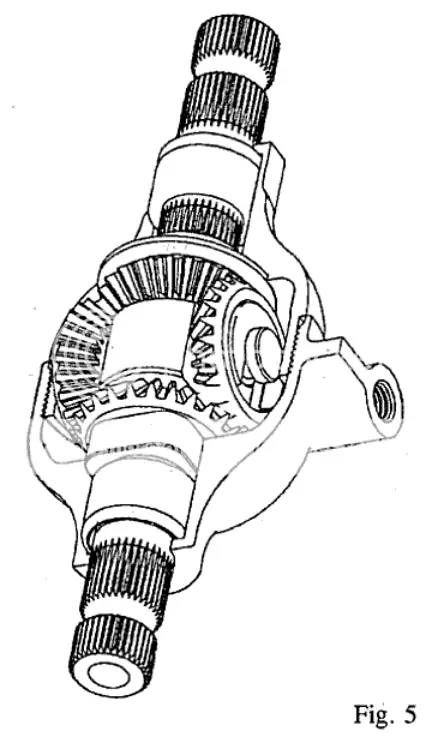

I chanced upon a google image of a "steering quickener" and was intrigued. It's a compact, very robust, lightweight, coaxial gearbox that is available in 1.5:1 and 2:1 ratios. There are a couple of other ratios but they are rarer.

Now the application of this as a dual-range gearbox would require some re-engineering. That's the fun part. I can see (see images below) where a shift fork or simple cam could be designed into this that would lock out the planetary gears and give 1:1 for high speed selection. Shifting it back to 2:1 (for instance) would make it low speed. Ideas would be appreciated. I'm going to buy one of these and work on it in the shop for a while.

The most promising thing about these gearboxes is that they are mass produced for race car applications which brings the price of a nicely engineered gearbox down from about 800-1000dollars to more like 125 dollars.

They are, obviously, designed for low-rpm high-torque. That means they might be suitable for way downstream in the transmission. Perfect for my project, maybe not so for yours.

Also, they don't appear to be designed to handle much radial loading. Again that's just fine for my project, but probably not good for the majority of applications in motorized bicycles or e-bikes.

Anyway, here are a few links to the beast in question. First one is the patent application for the original....

http://www.google.com/patents?id=4aCcAAAAEBAJ&printsec=abstract&zoom=4#v=onepage&q&f=false

Next is a pic some guy took of one he was about to put in a tractor....

http://i50.tinypic.com/343rogp.jpg

Finally a website for ordering one.....

http://www.scpraceparts.com/howe-racing-stealth-hd-steering-quickener.html

Obviously there would be a market for a selectable version of this. It's a very popular item among racers, especially guys refitting stock cars for racing. Being able to switch from OEM steering ratio to 2:1 with a simple lever would be desirable. I'm guessing that the corporate lawyers got in the way of that one right away. Idiotic misadjustment of a steering gearbox on a vehicle at 200+ mph is a lawsuit waiting to happen.

So.... any bright input on how to add a shift lever, sliding collar, dog clutch collar, lockout, etc, etc, to lock this into 1:1 when desired? For my particular project it would be the holy grail.