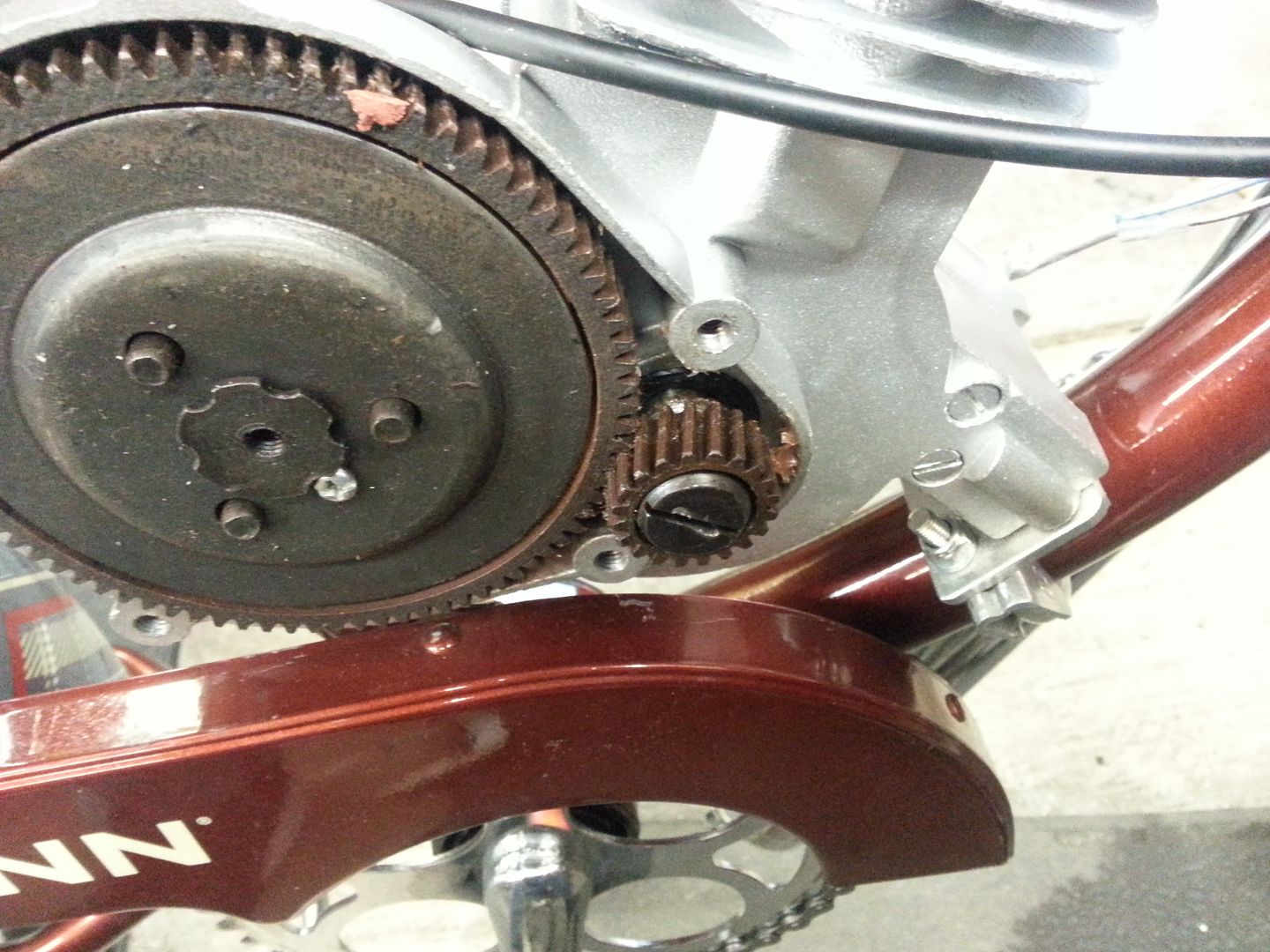

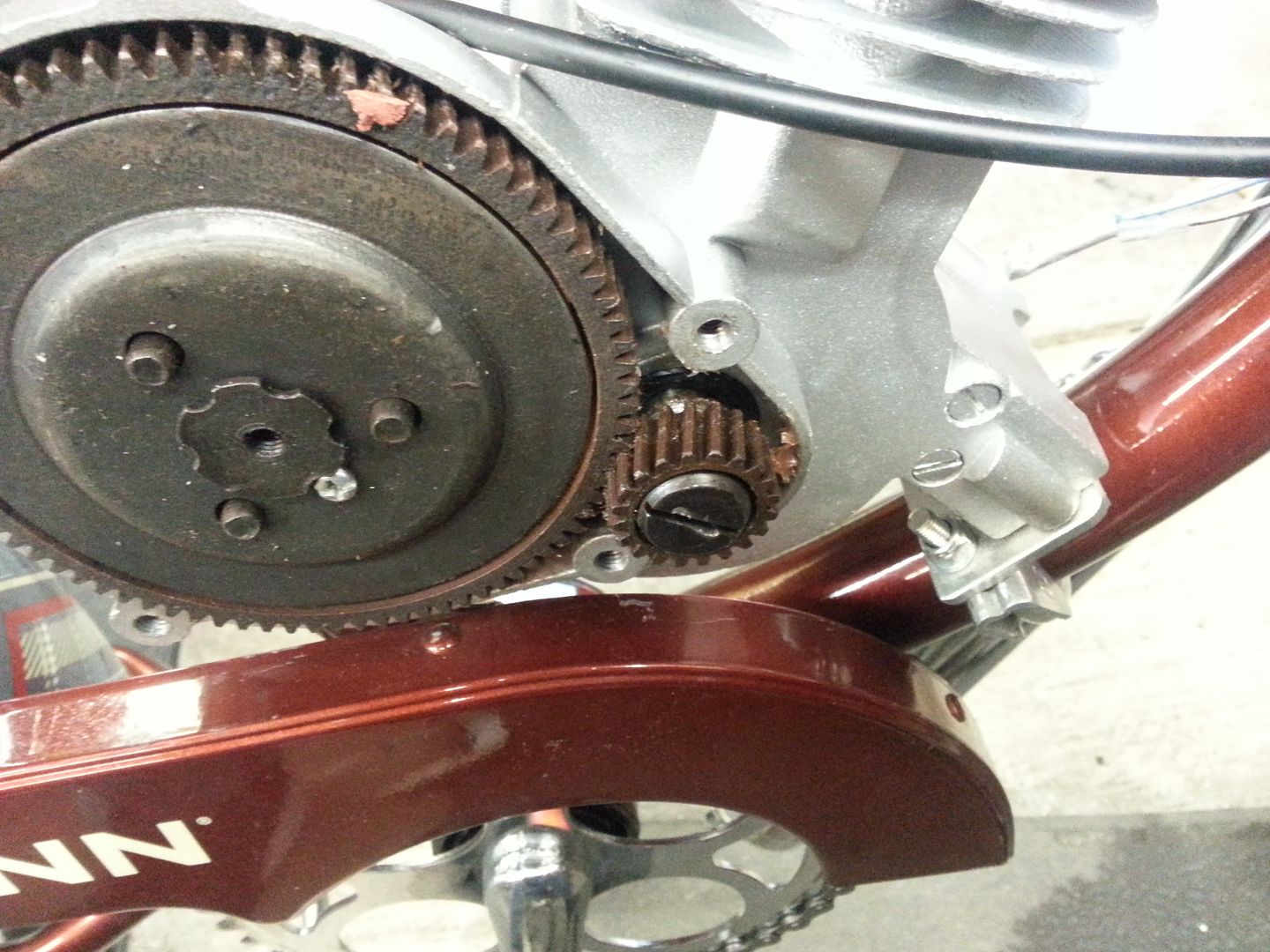

Map, what would you do with this one?

Came like this, brand new motor.

wow... that is a bad one although most all of them do stick a bit I think that is the worst one I've personally seen.

There's more than one way to make that one a bit better but each of the things I can think of are a bit hard to explain by just typing it out here on the computer, but I'll try my best to make a mental picture of what I'm thinking so you can follow me here, you may know exactly what I'm talking about but if not I'll try to explain by pix that I can take tomorrow that may help.

OK, first you will need to pull the small gear off of the crankshaft, be careful not to loose the small woodruff key, you will need some 180-220 grit emery cloth sandpaper, remove the mag cover on the other side and remove the spark plug, before I go any farther here, you will need the correct puller to get that gear off the shaft, some kits come with the puller and some don't, if you don't have one order one and dont take anything apart until you have it.

Now back on track, once you get spark plug out, mag cover off, clutch cover off, and the gear pulled off of shaft you will notice that the crankshaft is tapered, look to see if there is a bur on that taper that may be preventing the gear from seating all the way up as far as it should, if there is forget the sandpaper and get a fine to medium Flat bastard File and file the bur down flush maintaining the taper angle on the shaft as you file the high spot down, if there isn't a bur on the shaft it may be that the taper area was not turned down enough and that is why the gear will not go on the shaft as far as it needs to go, if this is the case then now is the time to get the emery cloth sandpaper, tear off an 8-10" piece from the roll, put it around the shaft so that you are holding one end of it between the fingers on one hand and the other end between the fingers with the other hand and while making sure that you maintain the correct angle you can start to use kind of a push pull motion back and forth with the sandpaper as it is wrapped in a horseshoe configuration around the shaft, the purpose of the spark plug being removed is so you can sand back and forth a few times and then you will want to rotate the engine so that its easy to equally sand around the shaft and not just in one place, just reach over and use the Flywheel/magnet to rotate the engine, just sand about 12-15 strokes and then rotate shaft 180 degrees/ half a turn and repeat, do this 8-10 times and then wipe of the shaft and just by hand ad hold the gear onto the shaft and see if it is going further up on the shaft until you get it to slide up about 1/8" further than it was before and then I would call it good. the gears dont have to be perfectly even for it to work just fine, perfectly even is great but none of mine are an I have not ever had an issue with them.

Another method would be to tare engine down, pull the crank and chuck it up in a lathe with the connecting rod attached to a piece of surgical tubing and attached to a stationary source so that the rod would not swing around and create major trouble when the lathe was running.

Another way that it could be done which may raise a couple eye brows here when I say this...LOL!

Would be to have a friend around because it will take two people to do this method.

if you have a drill that has a 1/2'' chuck you could have a buddy chuck the drill up on the flywheel nut, the spark plug will need to be removed for this also, spray a dab of lubricant into cylinder by way of the spark plug hole and have your friend run the drill at a medium speed while you hold the sandpaper or the file against the shaft again at the proper angle, the material will get removed much quicker this way so you will not want to wait very long bewteen times that you hold gear on shaft to check to see how it is fitting, if you remove to much material you may need to deepen the key way or at least file a little material off the bottom side of the woodruff key so it will allow the gear to be installed back on the shaft, don't spray a butt load of lube down in cylinder but dont run it very long in between giving it a quick spray to make sure the rings dont get dry against the cylinder wall.

Well, Pluto I hope you can follow what I tried my best to explain here, if you have a question just ask and I'll do my best to clear something up.

best wishes

Map