With my mountain bike down for frame repairs (which turned into frame replacement) and the stingray project temporarily on hold I decided to build another one so I have one I can get around on until I get the mountain bike back on the road... I also wanted something different so I went with a 700c fixie road bike. Instead of just taking my engine out and putting it in this one I went ahead and built a whole new engine for this bike and set it up to rev high.

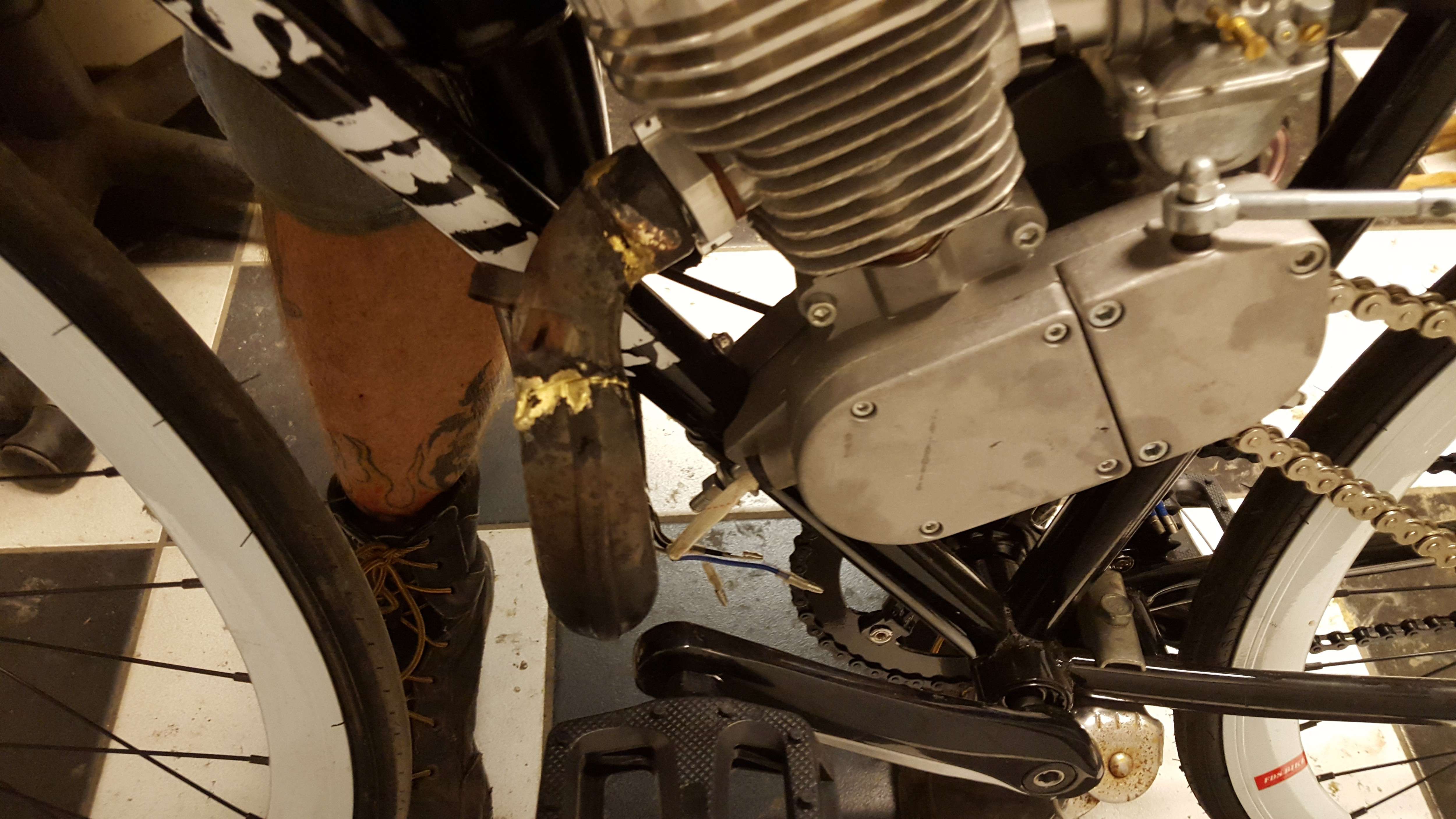

The rear sprocket wouldn't fit in the usual manner so I carefully enlarged the center hole in a 44 tooth sprocket until it fit over the lip on the fixed cog on the flip flop hub, welded it to the smaller cog and now it just screws on and then is locked in place by a second nut that's left hand threaded. No rag joint or adapter needed and the chain alignment with the engine came out perfect.

This one has the forged dropouts with built in chain adjusters which also made setting up the chain tension and rear wheel alignment super easy.

Even tho this bike is being built so I can take my time on the other 2 so they can be as nice as possible I'm not taking any shortcuts on this one either, it's just going together quicker since minimal modifications are needed.

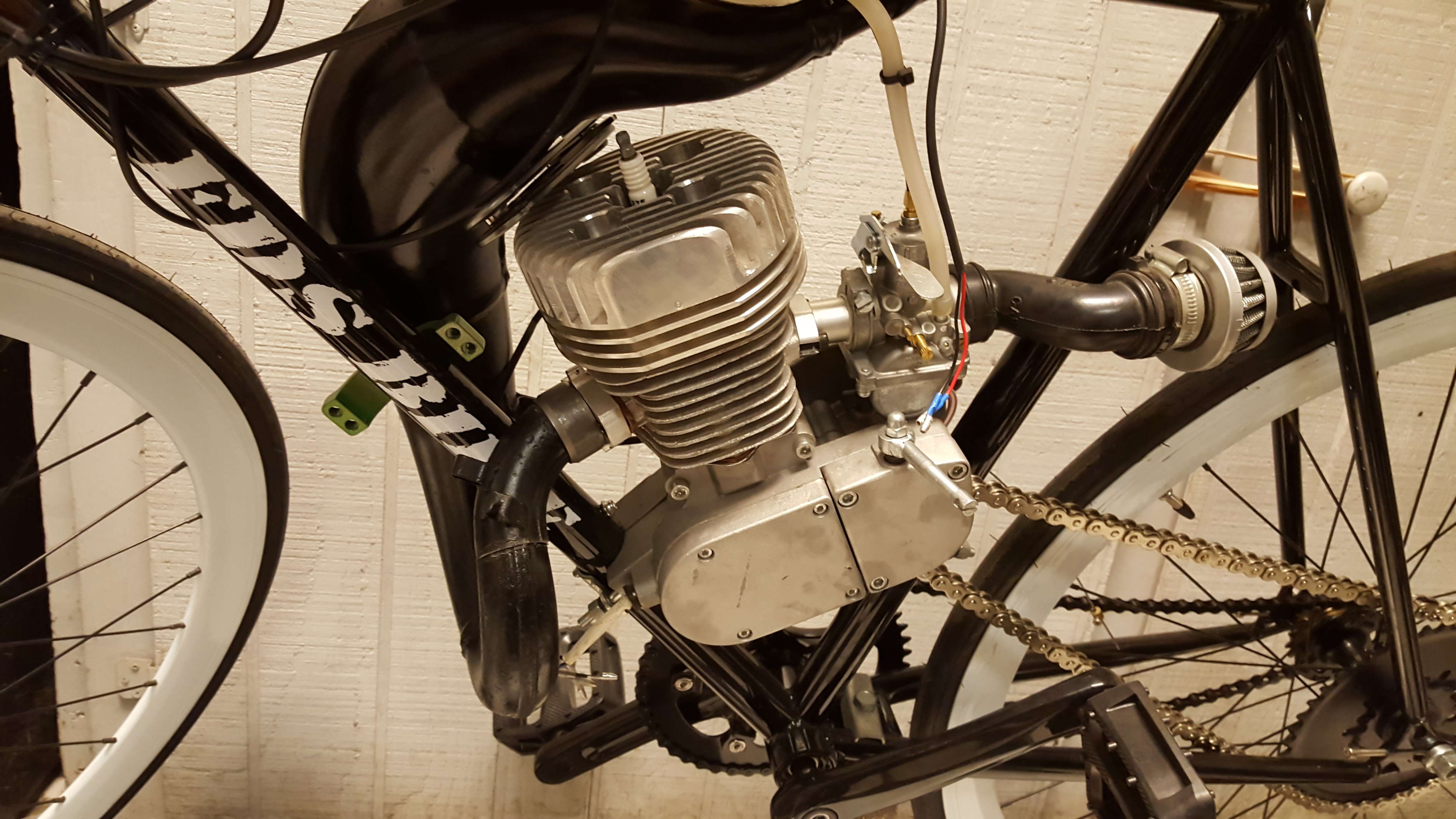

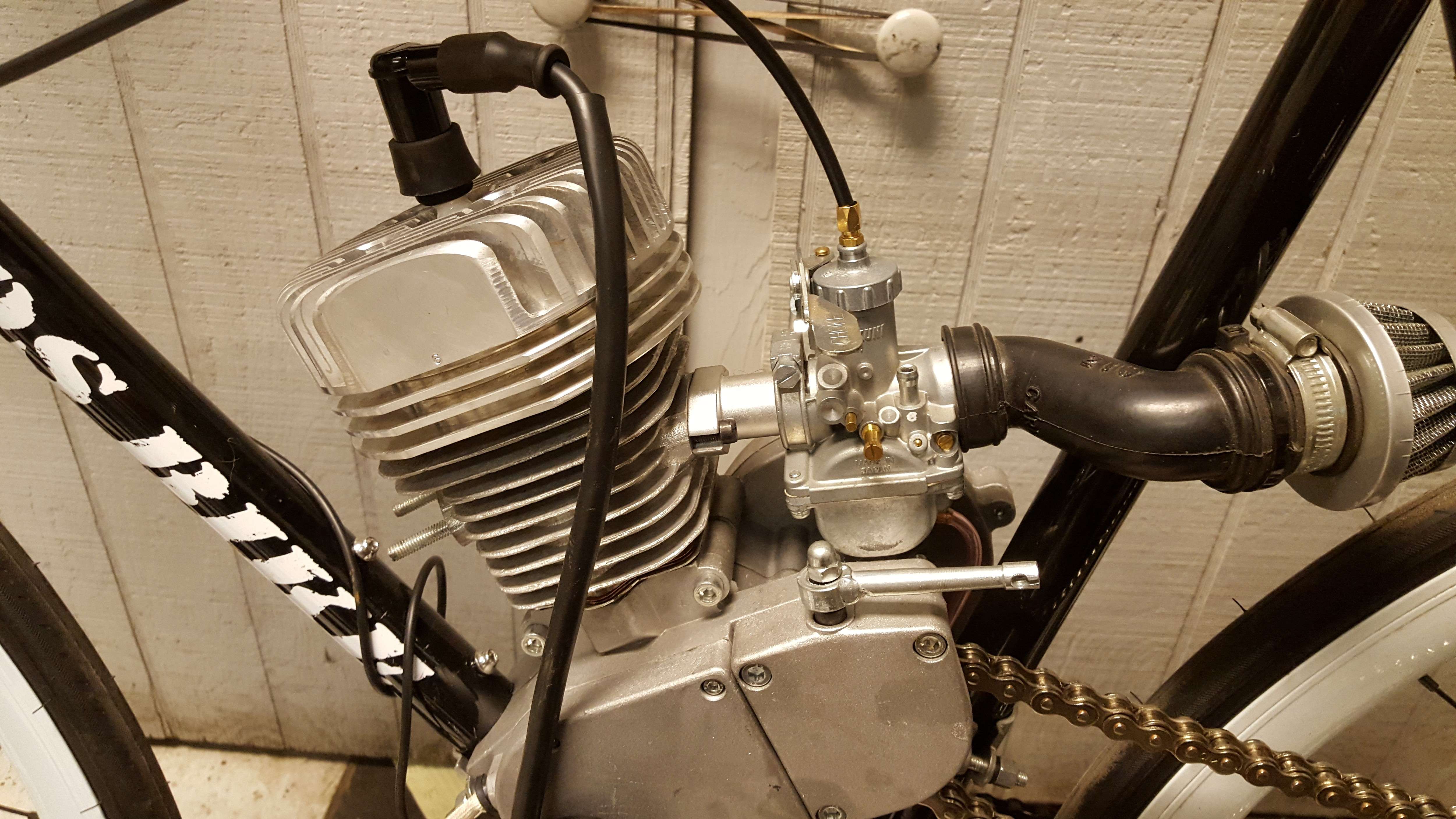

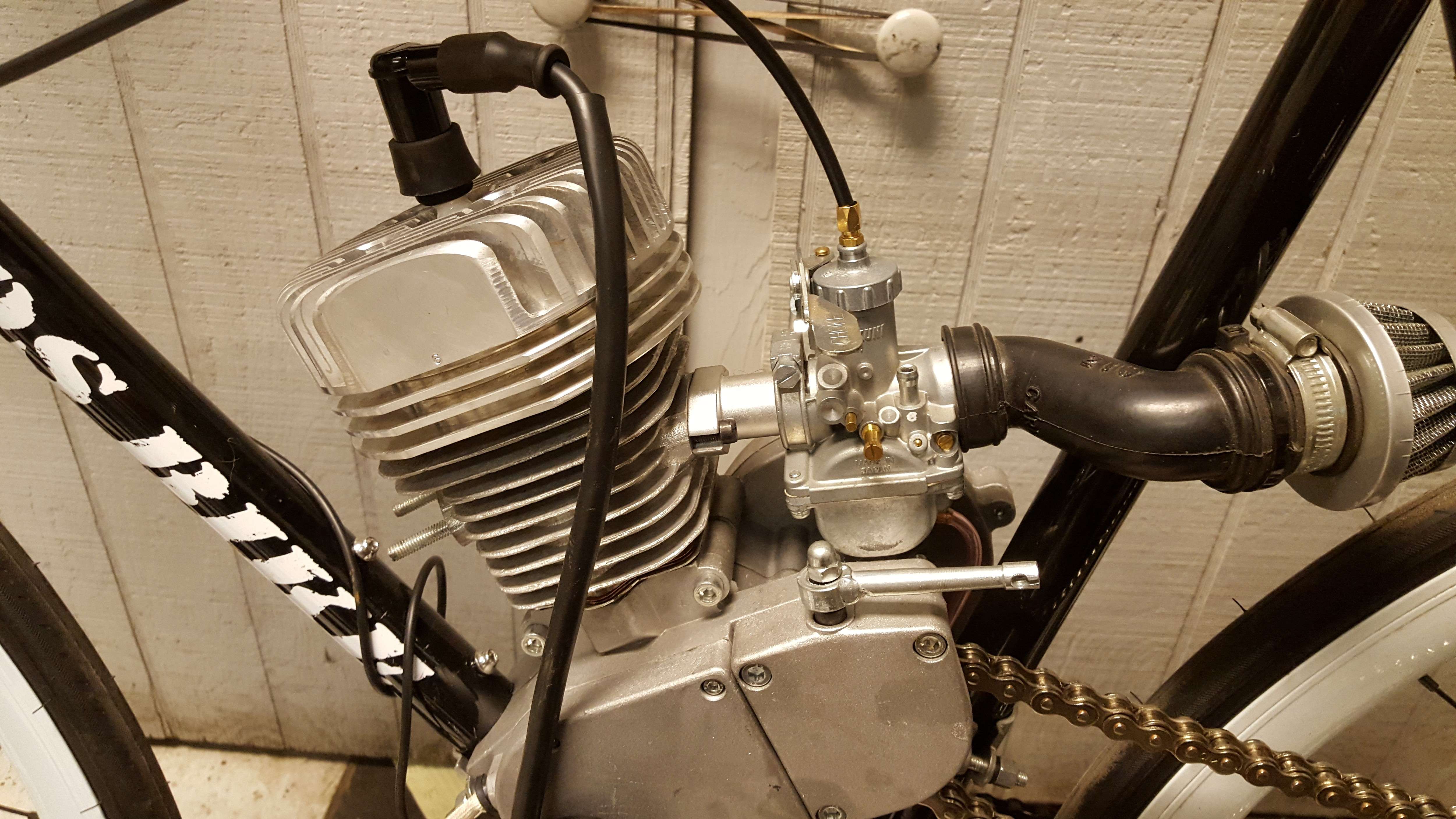

The chain is a KMC nickel plated 415H and it fits just right using a half link so no tensioner will be needed, the engine is a Dax bottom end with one of my ported jug's with the straight transfers, a 6cc Fred head, and an 18mm Mikuni to get enough air and fuel into the engine to take full advantage of the port work. This one has the exhaust port widened to 29mm and the roof raised 2mm to get the exhaust duration I wanted and the intake was also widened considerably with the intake floor lowered by 5mm . I also widened and re aimed the transfer tunnels as well as cleaning up any and all casting ridges then I raised the jug 2mm by using a 1mm spacer sandwiched between a set of copper base gaskets to increase transfer duration without giving up any blowdown. I'm working on making a KX65 pipe fit the engine and the bike so there will be no restrictions in the exhaust side either. Still deciding on what to do to quiet everything down but will most likely use a moto cross type silencer off an 80 to 125cc dirt bike.

I will buy and test fit a few different silencers then decide which one gives the best performance and runs the quietest.

I'm also planning on switching to a cloud 9 seat and possibly a suspension type seat post as well as a suspension stem if the ride is too harsh since this one uses really narrow street tires and they need to be inflated to 110 psi so they are rock hard as well.

Here are a few pics of this project as it sits today, I can only spend about an hour a day on this one since I get really busy really fast once I open up shop for the day and usually end up working late every evening so the only time I got is when I get to the shop an hour before I have to open up.

The rear sprocket wouldn't fit in the usual manner so I carefully enlarged the center hole in a 44 tooth sprocket until it fit over the lip on the fixed cog on the flip flop hub, welded it to the smaller cog and now it just screws on and then is locked in place by a second nut that's left hand threaded. No rag joint or adapter needed and the chain alignment with the engine came out perfect.

This one has the forged dropouts with built in chain adjusters which also made setting up the chain tension and rear wheel alignment super easy.

Even tho this bike is being built so I can take my time on the other 2 so they can be as nice as possible I'm not taking any shortcuts on this one either, it's just going together quicker since minimal modifications are needed.

The chain is a KMC nickel plated 415H and it fits just right using a half link so no tensioner will be needed, the engine is a Dax bottom end with one of my ported jug's with the straight transfers, a 6cc Fred head, and an 18mm Mikuni to get enough air and fuel into the engine to take full advantage of the port work. This one has the exhaust port widened to 29mm and the roof raised 2mm to get the exhaust duration I wanted and the intake was also widened considerably with the intake floor lowered by 5mm . I also widened and re aimed the transfer tunnels as well as cleaning up any and all casting ridges then I raised the jug 2mm by using a 1mm spacer sandwiched between a set of copper base gaskets to increase transfer duration without giving up any blowdown. I'm working on making a KX65 pipe fit the engine and the bike so there will be no restrictions in the exhaust side either. Still deciding on what to do to quiet everything down but will most likely use a moto cross type silencer off an 80 to 125cc dirt bike.

I will buy and test fit a few different silencers then decide which one gives the best performance and runs the quietest.

I'm also planning on switching to a cloud 9 seat and possibly a suspension type seat post as well as a suspension stem if the ride is too harsh since this one uses really narrow street tires and they need to be inflated to 110 psi so they are rock hard as well.

Here are a few pics of this project as it sits today, I can only spend about an hour a day on this one since I get really busy really fast once I open up shop for the day and usually end up working late every evening so the only time I got is when I get to the shop an hour before I have to open up.

Last edited: