jolfstn

Member

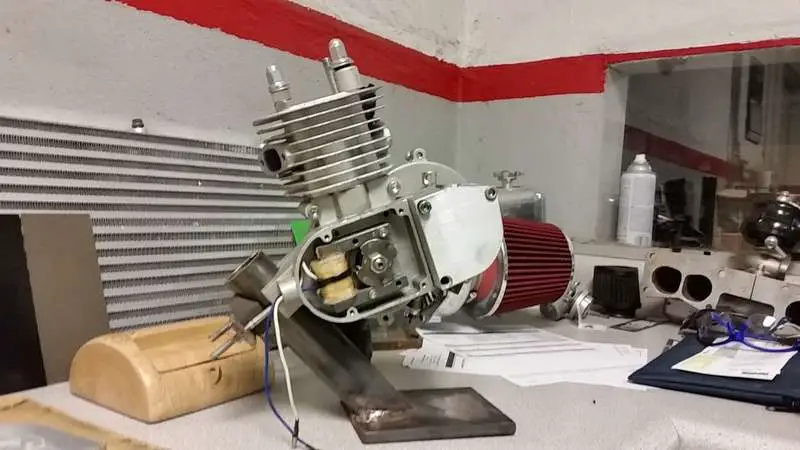

I have an extra HT motor and am considering fabricating a stand for my engine that will allow me to actually use & run the engine in order to test out modifications before putting it on my bike. I was thinking about a chain driven flywheel to give it a little resistance simulating actual use. Has anyone seen or made anything similar? I did a brief search and turned up nothing. Not a welder so a bolt up situation or maybe wood, or a combination. Juice Moto has a Youtube for a stand for working on your engine off your bike that could be a start but I am thinking something more involved. Any ideas?

I've been away some time. I just got a new motor from Bicycle Motor Works, this is the 3rd I've purchased from them, as well as some parts and lots of advice from the proprietor, Matt who's very helpful. Give him business he deserves it. Good products good prices and great service. (unsolicited just a happy customer)

My last one ran over a year before unknown problems inspired me to buy another one. The old one I'm thinking of building the stand for and getting it to run again that way. A year of almost daily use isn't bad considering its' a $100 piece of machinery composed of 115 year old technology. Happy motoring and any ideas on my operational stand would be helpful

I've been away some time. I just got a new motor from Bicycle Motor Works, this is the 3rd I've purchased from them, as well as some parts and lots of advice from the proprietor, Matt who's very helpful. Give him business he deserves it. Good products good prices and great service. (unsolicited just a happy customer)

My last one ran over a year before unknown problems inspired me to buy another one. The old one I'm thinking of building the stand for and getting it to run again that way. A year of almost daily use isn't bad considering its' a $100 piece of machinery composed of 115 year old technology. Happy motoring and any ideas on my operational stand would be helpful