You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Rat -- does a pull start fit?

- Thread starter cschade

- Start date

Davezilla

New Member

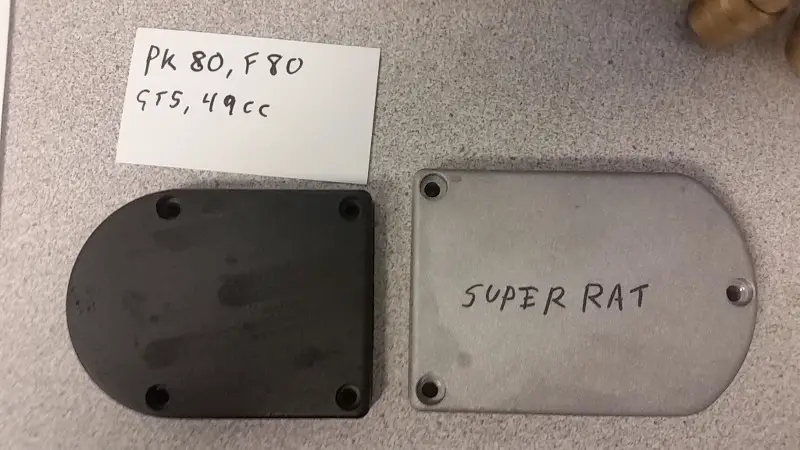

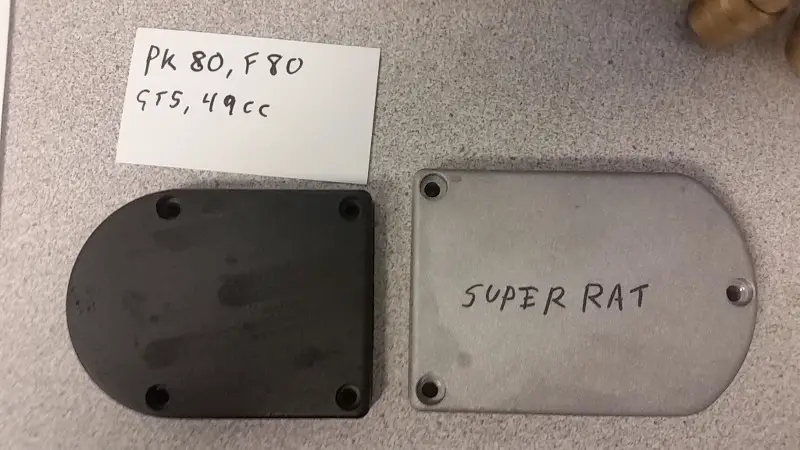

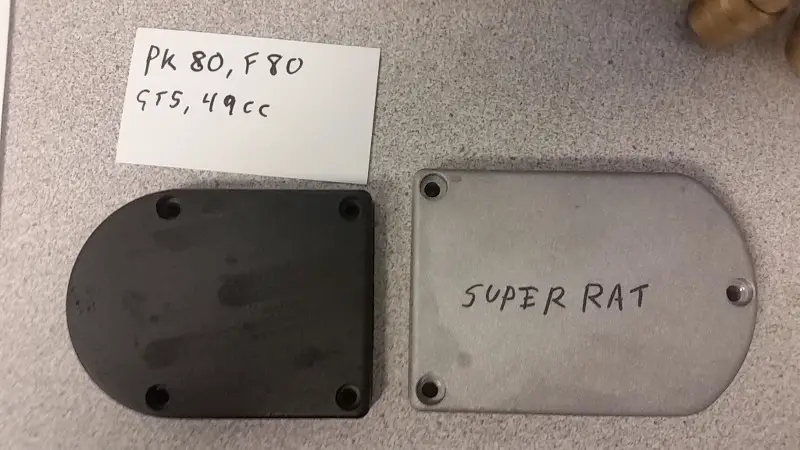

Nope... The pul start only fits the other 66cc engines, the suer rat has a much bigger side cover that bolts on with 3 screws and the standard engine bolts on with 4... I got both type engines at my shop and I can post a pic with the 2 side covers next to eachother to give an idea of how different they are...

Davezilla

New Member

The other problem is that the mag rotors are totally different but if you have access to a machine shop and the know how you could make up a pull starter, you would have to find a way to make a set of ratchet pawls or a one way roller clutch and come up with a way to fit a recoil winder to it and the mag rotor.

I will post pics of the 2 covers in the morning when I get to the shop... if you can build one then I would like to help you design it then you could build me one at the same time... I'm sure others would buy if you can make it look factory and easy to install on the engine without needing to modify the mag rotor etc... keeping the cost reasonable wont be easy tho...

I will post pics of the 2 covers in the morning when I get to the shop... if you can build one then I would like to help you design it then you could build me one at the same time... I'm sure others would buy if you can make it look factory and easy to install on the engine without needing to modify the mag rotor etc... keeping the cost reasonable wont be easy tho...

The other problem is that the mag rotors are totally different but if you have access to a machine shop and the know how you could make up a pull starter, you would have to find a way to make a set of ratchet pawls or a one way roller clutch and come up with a way to fit a recoil winder to it and the mag rotor.

I will post pics of the 2 covers in the morning when I get to the shop... if you can build one then I would like to help you design it then you could build me one at the same time... I'm sure others would buy if you can make it look factory and easy to install on the engine without needing to modify the mag rotor etc... keeping the cost reasonable wont be easy tho...

I'd love help designing it. I don't have access to more expensive machining equipment like lathes, milling machines, etc. but I do have all of the tools that I hope making it will require. I was hoping there might be a way to modify a traditional pull start to fit (I have one coming this week in the mail) Thoughts?

Davezilla

New Member

Ok... Here's the 2 covers to get a size and bolt pattern comparison.. All the GT5, PK80, F80, and other China Doll 49, 60, and 66cc engines use the smaller 4 bolt cover, but the Super Rat is different since it houses the larger mag rotor and the integrated CDI inside.

With the Super rat cover I would strongly recommend drilling a 1/2" hole where the center of the mag rotor is so the fan can pull in fresh cool air from outside, then blocking off the vent at the bottom rear corner and adding 3 or 4 1/4" holes at the lower front of the cover so the cooling air has to get sucked in from the center of the fan and blow over the cdi then exit at the front, the small vents at the bottom do practically nothing since no cool air can be drawn in.

To make a pul start, we will have a few challenges to overcome but may be able to use parts off a CAG engine or another small 2 smoker and find a way to mount the parts to the mag rotor and a modified case half... I gotta get busy at the shop already but I'll go into more details later...

Any and all help in designing this will be apriciated, I'm volunteering my help but always open to other suggestions and constructive criticism...

With the Super rat cover I would strongly recommend drilling a 1/2" hole where the center of the mag rotor is so the fan can pull in fresh cool air from outside, then blocking off the vent at the bottom rear corner and adding 3 or 4 1/4" holes at the lower front of the cover so the cooling air has to get sucked in from the center of the fan and blow over the cdi then exit at the front, the small vents at the bottom do practically nothing since no cool air can be drawn in.

To make a pul start, we will have a few challenges to overcome but may be able to use parts off a CAG engine or another small 2 smoker and find a way to mount the parts to the mag rotor and a modified case half... I gotta get busy at the shop already but I'll go into more details later...

Any and all help in designing this will be apriciated, I'm volunteering my help but always open to other suggestions and constructive criticism...

Ok... Here's the 2 covers to get a size and bolt pattern comparison.. All the GT5, PK80, F80, and other China Doll 49, 60, and 66cc engines use the smaller 4 bolt cover, but the Super Rat is different since it houses the larger mag rotor and the integrated CDI inside.

With the Super rat cover I would strongly recommend drilling a 1/2" hole where the center of the mag rotor is so the fan can pull in fresh cool air from outside, then blocking off the vent at the bottom rear corner and adding 3 or 4 1/4" holes at the lower front of the cover so the cooling air has to get sucked in from the center of the fan and blow over the cdi then exit at the front, the small vents at the bottom do practically nothing since no cool air can be drawn in.

To make a pul start, we will have a few challenges to overcome but may be able to use parts off a CAG engine or another small 2 smoker and find a way to mount the parts to the mag rotor and a modified case half... I gotta get busy at the shop already but I'll go into more details later...

Any and all help in designing this will be apriciated, I'm volunteering my help but always open to other suggestions and constructive criticism...

what is the height of your mag cover on the super rat and the regular engine? Height of my Dragon Fire cover is 3 inches and im now curious to see if there is any difference between the Dragon Fire and Super Rat

you dont need a complicated mechanism, all you need is a metal "cup" (dont know what they are actually called but I'll explain what they are). On engines with external flywheels, the pullstart mechanism is attached to the flywheel cover, but the "cup" part, which is what the pullstart mechanism actually turns, is attached to the flywheel itself. But you dont need a pullstart, all you need is a rope, wrap it around the cup and pull it, there you go. Just need to find or make a "cup" that can fit through the mag cover. you would obviously need to cut a hole in the mag cover for it, but it would have to be smaller than 3". I will find a link to an image of the "cup" part im referring to.

https://sp.yimg.com/ib/th?id=JN.HvgSY1Gi/8pmsmGE8NJLoA&pid=15.1&P=0 The part on top of the flywheel fan, which is the white plastic part with fins all around it for anyone unfamiliar with 4 stroke flywheels. Something like that could be adapted, like I said wrap a rope around it and pull the rope.

Davezilla

New Member

That would work on a briggs type engine, but there's a risk of bending the crank on one of these since these are cut down to a much smaller shaft diameter where the mag rotor bolts on... Using the rope directly on the mag rotor or a sheave attached to the rotor would put too much side load on the crank when pulled, the end of the crank would need to be supported somehow like making up something similar to the regular china doll pull starter, but if one was to design a support bearing then bolt a small gear to the end of the rotor, a zip starter would be fairly easy to design, the zip starter uses a plastic "zipper" that's basically a piece of flexible or semi rigid plastic with teeth molded in or machined in and a pull handle on one side, the zipper is fed thru and quickly pulled out, the drawback of a zip starter tho is that the zipper needs to be stored on the bike when not in use like while riding or left at home but then you couldn't shut the engine down if you have a centrifugal clutch or a jack shaft where bump starting couldn't be possible.

The other drawback is that the engine can shoot the zipper out if it starts early in the pull.

Feeding the "zipper into the start slot on the side of the engine can be made easy by using a one way bearing to mount the gear to the mag rotor, this could be pressed onto the rotor and the gear pressed onto a one way bearing, then once done this way it couldn't spit out the zipper violently if the engine starts before it's pulled all the way out.

Back to pull starting, the easiest method would be to copy a China doll pull starter but with the right sized case cover, then use a bendix type pawl that would push out and engage with the mag rotor, this eliminates the side load on the mag rotor and retracts out of the way once the engine is started or the rope is released... We could use a CAG start pawl for this since this is how these are designed, now we need a CAG pull starter and a way to mount the recoil and pawl setup to a stock mag cover, and the other half of the pawl to mount to the end of the crank... I got an idea and a CNC router that can make the parts, but not a lot of time to mess with it, but maybe if we use Cag starter parts we can get one successfully built a little quicker...

Still would like to hear some more inputs, but this might be the easiest way to get one made.

The other drawback is that the engine can shoot the zipper out if it starts early in the pull.

Feeding the "zipper into the start slot on the side of the engine can be made easy by using a one way bearing to mount the gear to the mag rotor, this could be pressed onto the rotor and the gear pressed onto a one way bearing, then once done this way it couldn't spit out the zipper violently if the engine starts before it's pulled all the way out.

Back to pull starting, the easiest method would be to copy a China doll pull starter but with the right sized case cover, then use a bendix type pawl that would push out and engage with the mag rotor, this eliminates the side load on the mag rotor and retracts out of the way once the engine is started or the rope is released... We could use a CAG start pawl for this since this is how these are designed, now we need a CAG pull starter and a way to mount the recoil and pawl setup to a stock mag cover, and the other half of the pawl to mount to the end of the crank... I got an idea and a CNC router that can make the parts, but not a lot of time to mess with it, but maybe if we use Cag starter parts we can get one successfully built a little quicker...

Still would like to hear some more inputs, but this might be the easiest way to get one made.

cannonball2

Well-Known Member

Keep your leg out of it!