You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

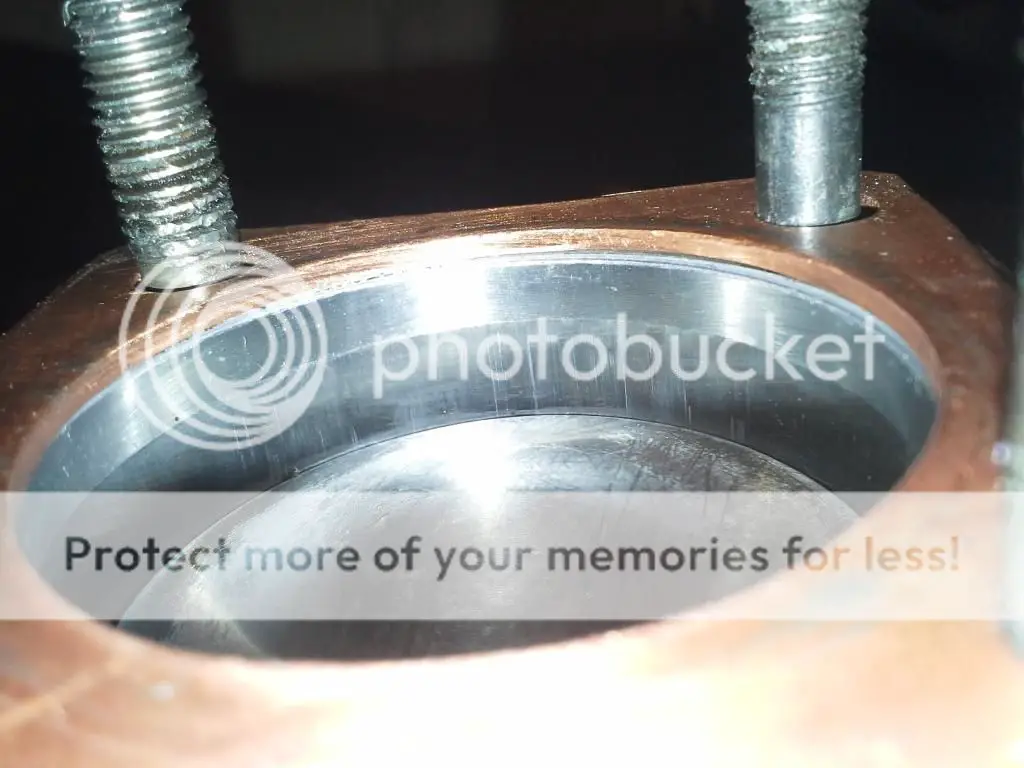

copper gasket ..Calling all pro's

- Thread starter Jumpa

- Start date

crassius

Well-Known Member

from motorcycle experience, copper & aluminum are pretty much equivalent in function

as to thick vs thin, that will change compression a bit, or provide clearance for longer spark plugs, but not different from using 2 gaskets when needed

I'd say that you'll see no real diff

as to thick vs thin, that will change compression a bit, or provide clearance for longer spark plugs, but not different from using 2 gaskets when needed

I'd say that you'll see no real diff

rogergendron1

New Member

Copper is nice ... I run a soft aluminum gasket though as I think it compresses a little better and is a bit softer . When I make my own gaskets for these motors I make the gaskets to spec. As in exactly the size I need

I would run a 1.6 mm base gasket and a .4mm head gasket . I use a thicker base to raise the jug up a lottle then I deck it back down to where it waz. This raises the ports and gives a performace boost, then I go from stock 1mm to a thin .4mm head gasket this alows the chamber squish to be closer to the pison making it more effective and also boost compression a little.

The gasket you made looks a little thick ...with a gasket that thick you may render any squish band you have ineffective as it will be up and away from the piston at TDC. Remember the closer the piston crown to the squish bamd the more effective it will be, do what you need to to get the comp and squish hight right.. Deck the jug on sand paper and glass to bring the piston closer to

the deck, also use a gasket thin enough to keep the piston dome close enough to the heads squish band, lastly deck the head for the desired comp ratio.

Copper gaskets are the bezt and usually last the life of the motor unless they get bent

You can deck your jug to makeup for the thickness of your head gasket if you want to keep using it just deck it down untill the piston comes to the proper deck hight with the gasket on the jug.

I would run a 1.6 mm base gasket and a .4mm head gasket . I use a thicker base to raise the jug up a lottle then I deck it back down to where it waz. This raises the ports and gives a performace boost, then I go from stock 1mm to a thin .4mm head gasket this alows the chamber squish to be closer to the pison making it more effective and also boost compression a little.

The gasket you made looks a little thick ...with a gasket that thick you may render any squish band you have ineffective as it will be up and away from the piston at TDC. Remember the closer the piston crown to the squish bamd the more effective it will be, do what you need to to get the comp and squish hight right.. Deck the jug on sand paper and glass to bring the piston closer to

the deck, also use a gasket thin enough to keep the piston dome close enough to the heads squish band, lastly deck the head for the desired comp ratio.

Copper gaskets are the bezt and usually last the life of the motor unless they get bent

You can deck your jug to makeup for the thickness of your head gasket if you want to keep using it just deck it down untill the piston comes to the proper deck hight with the gasket on the jug.

I agree with all said, but if your not after the best possible performance, then I'd just put it back together, Do a Compression test on it if you want.

But unless it's a high performance thing squish bands and such don't really mean much.

If you are after performance, do a squish test, without head gasket first.

I use a piece of 1mm solder, across the top of piston, head back on, turn her over, check solder ends with a vernier.

Unless you can get your final squish down to less than 1mm it won't do a thing.

If you have an angle fire head and you do get your squish to less than 1mm then you'll probably have more compression than you want.

But unless it's a high performance thing squish bands and such don't really mean much.

If you are after performance, do a squish test, without head gasket first.

I use a piece of 1mm solder, across the top of piston, head back on, turn her over, check solder ends with a vernier.

Unless you can get your final squish down to less than 1mm it won't do a thing.

If you have an angle fire head and you do get your squish to less than 1mm then you'll probably have more compression than you want.

The important thing is making sure you have absolutely flat gasket sealing surfaces. Lap the head and cylinder to assure that the mating surfaces are flat, flush and true and then almost any gasket will suffice. Trying to 'fix' a poor sealing surface with a gasket is a study in futility no matter the material.

Tom

Tom

dodge dude94

New Member

Personally, I'd run as thin a gasket as possible to get the most compression otherwise low end will suffer a bit.

On my better motors I make copper head, base, inlet and exhaust gaskets.

A Jeweler's fret saw? is the go.

These gaskets then are very handy when match porting.

What thickness was the cooper sheet you used ?

rogergendron1

New Member

If i were to run a thick head gasket i would just deck the jug the equivelant of the thickness of the gasket you made then dexk the head for desired comp ratio

Davezilla

New Member

I use the copper base and head gaskets exclusively on my builds as well, I like to be able to set my squish and port hight and know they won't move or change once torqued down and in service, The biggest advantage tho is that these can be reused over and over again. Right now I'm still buying mine from Juice and they alwas come to me well packaged and never bent. The base gaskets usually need a little trimming to match my transfers but that doesn't take any time at all during assembly.

My last build I wanted to use my old jug on a Dax Gen IV bottom end and the piston was too high so I made an aluminum shim at the base, double checked my timing and used a combination of a single .016 and .025" head gaskets which I glued together with a really thin coat of gasket shellac. I also use a very thin coat of shellac on the base gasket and shim for a perfect leak free seal everytime. The shellac holds up very well and when put on really thin there's no issues with squeeze out into your cylinder or case, absolutely no issues with even the smallest leaks, and disassembly is still nice and easy.

The use of shellac or sealants isn't needed at all if using a single gasket, but it doesn't hurt anything if used very sparingly.

Anytime you need to reuse one of these gaskets it's always a good idea to anneal the copper to ensure the best possible seal.

My last build I wanted to use my old jug on a Dax Gen IV bottom end and the piston was too high so I made an aluminum shim at the base, double checked my timing and used a combination of a single .016 and .025" head gaskets which I glued together with a really thin coat of gasket shellac. I also use a very thin coat of shellac on the base gasket and shim for a perfect leak free seal everytime. The shellac holds up very well and when put on really thin there's no issues with squeeze out into your cylinder or case, absolutely no issues with even the smallest leaks, and disassembly is still nice and easy.

The use of shellac or sealants isn't needed at all if using a single gasket, but it doesn't hurt anything if used very sparingly.

Anytime you need to reuse one of these gaskets it's always a good idea to anneal the copper to ensure the best possible seal.

mapbike

Well-Known Member

I use the copper base and head gaskets exclusively on my builds as well, I like to be able to set my squish and port hight and know they won't move or change once torqued down and in service, The biggest advantage tho is that these can be reused over and over again. Right now I'm still buying mine from Juice and they alwas come to me well packaged and never bent. The base gaskets usually need a little trimming to match my transfers but that doesn't take any time at all during assembly.

My last build I wanted to use my old jug on a Dax Gen IV bottom end and the piston was too high so I made an aluminum shim at the base, double checked my timing and used a combination of a single .016 and .025" head gaskets which I glued together with a really thin coat of gasket shellac. I also use a very thin coat of shellac on the base gasket and shim for a perfect leak free seal everytime. The shellac holds up very well and when put on really thin there's no issues with squeeze out into your cylinder or case, absolutely no issues with even the smallest leaks, and disassembly is still nice and easy.

The use of shellac or sealants isn't needed at all if using a single gasket, but it doesn't hurt anything if used very sparingly.

Anytime you need to reuse one of these gaskets it's always a good idea to anneal the copper to ensure the best possible seal.

Excellent advice Davezilla

Do you use the old Indian Head Shellac?

I normally use the Permatex Aviation really stringy and messy stuff, but I plan to just give my copper gaskets a good light coat of copper coat gasket spray sealer or a light coat of silver spray paint which has also always worked good for me as a little extra insurance type sealer.

Map

Davezilla

New Member

I've used the permatex stuff before but I've always ended up going back to my favorite, the trusty Old Indian Head... which is now made by Permatex, but they kept it the same and didn't change it in any way.

Copper gasket spray and silver spray paint also work well for me and I've used both over the years, they both work really really well on MLS head gaskets where sealant normally isn't required just for added assurance it won't leak.

I'm still using Juice's copper gaskets exclusively since they're laser cut and really nice, the transfer area usually needs to be matched up on his base gaskets but it's better to have a little extra material there so they'll fit any of these engines and then the end user or builder can trim them to fit perfectly. IF he made them fit one engine perfect, they probably wopuld be a little off on another engine so leaving a little extra material in that area is a good idea.

Hopefully after I get my business up and running I can slip in a CNC router when I buy my equipment, then I'll be able to make my own copper and aluminum gaskets, spacers, etc as well as just about any small part that's made of aluminum or other soft metals or plastics etc. , but for now Juice makes a really really good product and I'll continue to buy his gaskets. His other gaskets like the case, and the intake/exhaust are all copper sprayed over high quality gasket paper so anyone could buy his paper gaskets and spray the copper on themself, but I'd really like it if he started making a copper exhaust gasket that's about .080" thick. RSE has solid copper exhaust gaskets, but they cost $20 to ship to Texas so unless I'm buying like 10 or more it's not very practical, but the quality is there and would never blow another exhaust gasket.

Copper gasket spray and silver spray paint also work well for me and I've used both over the years, they both work really really well on MLS head gaskets where sealant normally isn't required just for added assurance it won't leak.

I'm still using Juice's copper gaskets exclusively since they're laser cut and really nice, the transfer area usually needs to be matched up on his base gaskets but it's better to have a little extra material there so they'll fit any of these engines and then the end user or builder can trim them to fit perfectly. IF he made them fit one engine perfect, they probably wopuld be a little off on another engine so leaving a little extra material in that area is a good idea.

Hopefully after I get my business up and running I can slip in a CNC router when I buy my equipment, then I'll be able to make my own copper and aluminum gaskets, spacers, etc as well as just about any small part that's made of aluminum or other soft metals or plastics etc. , but for now Juice makes a really really good product and I'll continue to buy his gaskets. His other gaskets like the case, and the intake/exhaust are all copper sprayed over high quality gasket paper so anyone could buy his paper gaskets and spray the copper on themself, but I'd really like it if he started making a copper exhaust gasket that's about .080" thick. RSE has solid copper exhaust gaskets, but they cost $20 to ship to Texas so unless I'm buying like 10 or more it's not very practical, but the quality is there and would never blow another exhaust gasket.

mapbike

Well-Known Member

Well, Davezilla

Sounds to me like you may want to supply us with a couple of things you mentioned here once you get set up, a nice copper exhaust gasket would be somethingyou could makea batch of and peddle to us, I'd buy any of the gaskets you made up for mine, I'll support a forum member over others on parts and pieces like that and I'm sure many others feel the same way.

Map

Sounds to me like you may want to supply us with a couple of things you mentioned here once you get set up, a nice copper exhaust gasket would be somethingyou could makea batch of and peddle to us, I'd buy any of the gaskets you made up for mine, I'll support a forum member over others on parts and pieces like that and I'm sure many others feel the same way.

Map