Kestrel Motors Inc.

New Member

Which do you prefer Belts or chains? I myself prefer the older style of the belts. But why do you like either of them?

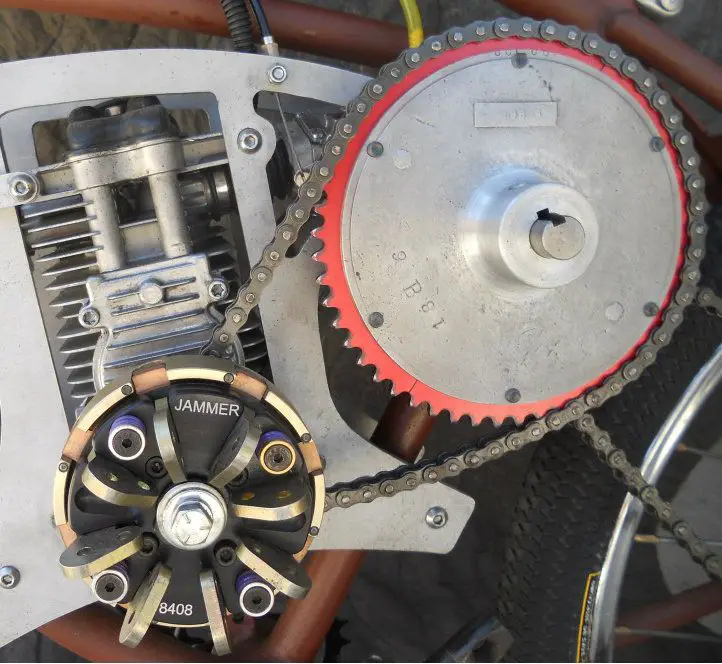

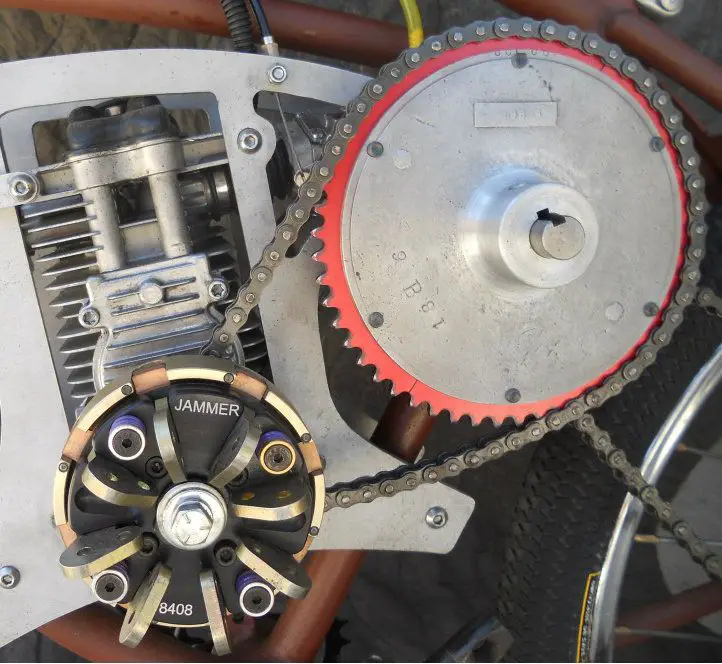

Well, truth be told, that's what I did too, only reversed! Chain primary and belt secondary.

I prefer belt primary and final drive for most of my bikes because of low noise and maintenance, no oil slinging and alignment isn't as critical.

Chains offer more efficient power transfer and don't stress your bearings as much as a tight belt, so I may use chains on my next race bike. I have one bike with belt primary and chain final.

I also have one with chain primary and final.

After the last race at Grange, I'm seriously considering a friction drive racer.

Yeah, I must say I have a sweet love for all pulleys and belts XD, I don't know why, I just like them much better than chains. Chains have good torque transmission, and belts tend to slip a little, but that's all part of the fun!