Hi guys, here she is, the Hustler. She doesn't quite live up to her name yet, but I call her that because I'm tuning her to be FAST even though she won't look fast. I started with an ugly oddball bike that was filled with problems. The brakes sucked and the frame sucked and the wheels sucked. IT SUCKED. The mounts were splayed out on the front because the tube was too big. That kind of stuff makes me grit my teeth.

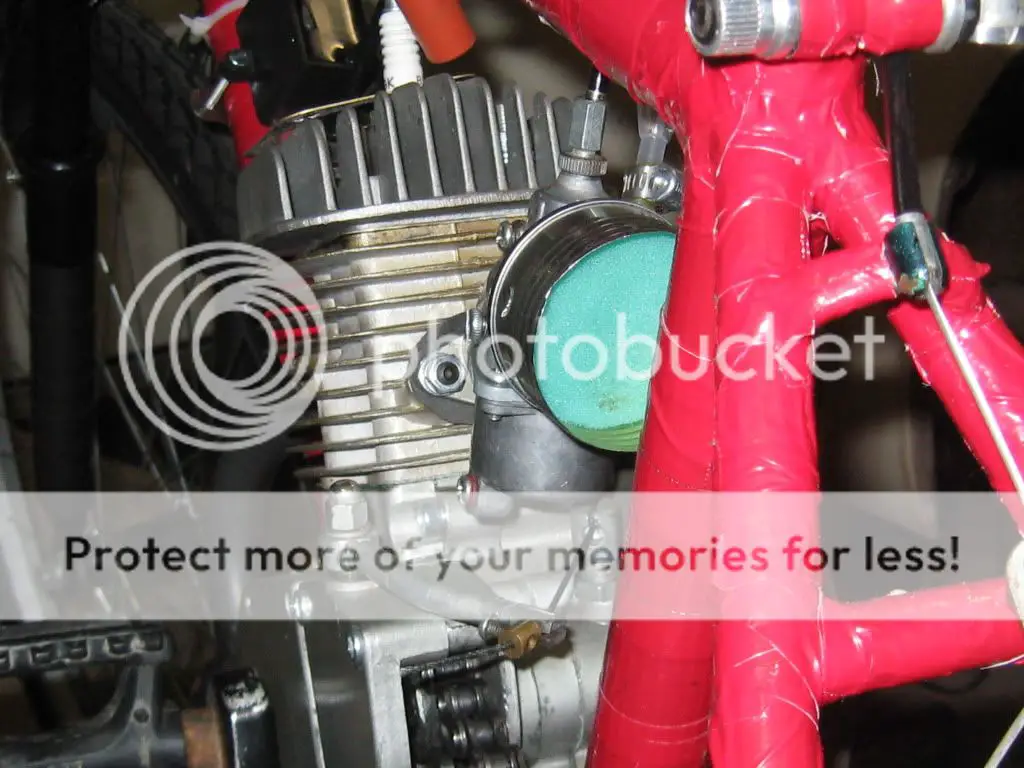

The engine though, is a PK80, and boy does it have power! I did an initial cleaning of the entire engine and, I clean and rebuilt the carb, and I put on a straight plug head with a single gasket because, well, I don't like slant heads. I repacked the rear wheel bearings and had the front and rear wheels trued. The frame I used is an old diamondback frame that actually fits the stock mounts without splaying them out (praise the lord) I got a hardware kit and headbolt kit from sbp and the quality ROCKS. I also got a good carb gasket from them because the original engine had NO GASKET .

.

The front fork is a gas shock and you don't want to know what I had to go through to get it to fit right. I decided that to contribute to the hustler appearance I'd wrap the frame in red duct tape as a kind of bastard ferrari paint. The tires are kevlar reinforced 1.75" with slime tubes inside. I put on skull valve caps and made a special seat cover. The clutch cable is the teflon coated and the exhaust is just a cut off muffler (it hurts my ears lol) It's pretty impressive to see the before and after. I had to work hard to make the brakes and wheels and chain and everything work well on this bike. Both derailures are removed so it is a single speed now. That's all I have to say about it for now. Once I do a port and balance job with new bearings (japanese nachi bearings) and an sbp pipe it should be a real hustler. I can't wait to do more work, but I whipped it together now so that I could go to the rally this weekend! I also started my first gallon of opti2 these are good times!!! here are pics, before and after. Enjoy

Before:

After:

The engine though, is a PK80, and boy does it have power! I did an initial cleaning of the entire engine and, I clean and rebuilt the carb, and I put on a straight plug head with a single gasket because, well, I don't like slant heads. I repacked the rear wheel bearings and had the front and rear wheels trued. The frame I used is an old diamondback frame that actually fits the stock mounts without splaying them out (praise the lord) I got a hardware kit and headbolt kit from sbp and the quality ROCKS. I also got a good carb gasket from them because the original engine had NO GASKET

The front fork is a gas shock and you don't want to know what I had to go through to get it to fit right. I decided that to contribute to the hustler appearance I'd wrap the frame in red duct tape as a kind of bastard ferrari paint. The tires are kevlar reinforced 1.75" with slime tubes inside. I put on skull valve caps and made a special seat cover. The clutch cable is the teflon coated and the exhaust is just a cut off muffler (it hurts my ears lol) It's pretty impressive to see the before and after. I had to work hard to make the brakes and wheels and chain and everything work well on this bike. Both derailures are removed so it is a single speed now. That's all I have to say about it for now. Once I do a port and balance job with new bearings (japanese nachi bearings) and an sbp pipe it should be a real hustler. I can't wait to do more work, but I whipped it together now so that I could go to the rally this weekend! I also started my first gallon of opti2 these are good times!!! here are pics, before and after. Enjoy

Before:

After: